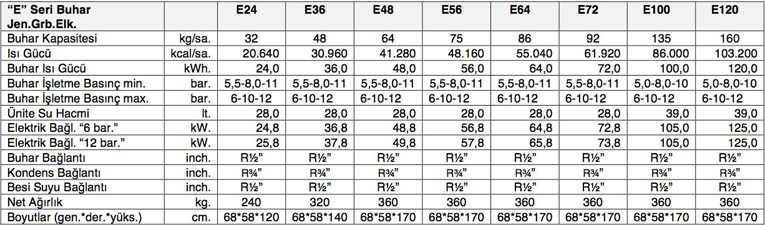

Electrically Heated E - Series

Unparalleled Process Monitoring and Ease of Use provided by the use of high-capacity CPU and 7” Touch Screen.

Ergonomic Module, made of completely stainless steel material, which provides maximum space saving by integrating into the generator body.

Flexible Working System provided by the use of Standard (15 kW/unit) Heating Resistance. (The advantage of enabling the desired number of Resistance Groups according to the steam requirement.)

Hygienic Steam Production Opportunity provided by the use of 304L or 316L stainless steel material on all surfaces in contact with water.

Electrically Heated E - Series

E SERIES STEAM GENERATORS

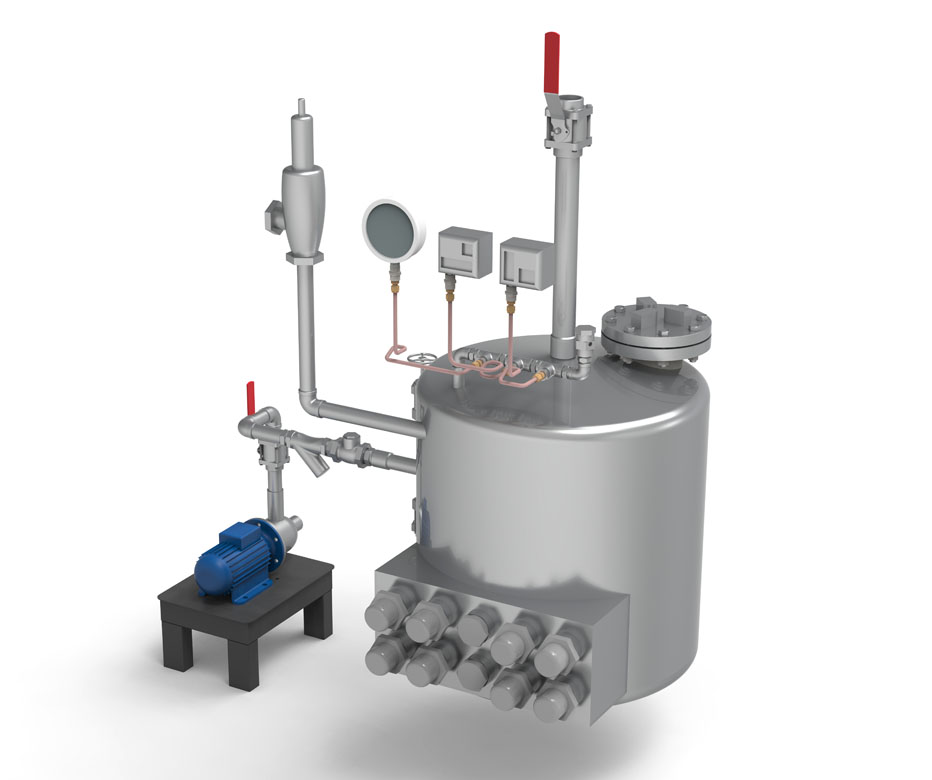

- Fully Safe Vertical Design, designed for Low Capacity (20-100 kg/h) and Medium Pressure (2-6 bar) steam generation.

- High Efficiency Working System. (Yield:>98.5% avg.)

- Low Water Volume Design with no risk of explosion damage (death etc.). “97/23EC Category III: V(lt.)*P(bar)<1.000”

- Heavy Duty Body Construction designed for P quality sheet and pipe use in accordance with international norms (97/23EC).

- Hygienic Steam Generator option designed with the use of AISI304L or 316L materials on surfaces in contact with water.

- PLC Control Module where all process parameters can be monitored and controlled precisely.

- The advantage of the Gradual Working System provided by the use of Standard Resistance Group (15 kW/unit).

- Control Panel in accordance with the norms where the command/control fixtures (Schnedier, Omron, etc.) selected in accordance with international standards are collected.

- Digital Error Indicator that checks negative external factors (water cut, chimney clogging, etc.).

- Fail Proof Design using Control and Safety Elements (Pressure Switches, Pressure and Temperature Transmitters, Safety Valve, Pump).

- Condensate Tank obsy.

- Energy Saving with short (˂8-12 min.) start time due to low water volume.

- Body-bound Steam Tub that controls the feed water level and process temperatures.

- Horizontal Feed Water Pump with high pressure, conforming to international standards (Grundfos etc.).

- Possibility of adding electronic Electricity and Water Flowmeters to the system to monitor operational consumptions.

- Possibility to add electronic Conductivity, Hardness and pH Control Module to control system inputs.

- TSEK Quality Certificates.